Maximizing Result: The Force of an Automated Clothing Factory

In the present speedy design industry, proficiency and result are basic for progress. Automated clothing factories are emerging as huge advantages, offering phenomenal abilities to amplify creation while maintaining quality. This article investigates the force of automation in piece of clothing manufacturing, highlighting how these advanced factories are boosting yield, reducing expenses, and setting new standards in the industry.

Outline

Importance of proficiency and result in the design industry

The job of automation in enhancing article of clothing creation

Background

Customary article of clothing manufacturing and its constraints

The shift towards automation in the design industry

Key advances driving automation in clothing factories

Key Parts of Automated Clothing Factories

Mechanical sewing machines

Automated texture cutting frameworks

Artificial intelligence driven quality control

Integrated creation management programming

Advantages of Maximizing Result with Automation

Increased creation speed and volume

Consistent quality control and decreased absconds

Cost savings through decreased work and material waste

Adaptability and versatility underway

Influence on the Style Industry

Quicker times required to circle back and speed to showcase

Enhanced seriousness and benefit

Meeting the demands of quick style and custom orders

Sustainable creation rehearses and diminished ecological effect

Difficulties and Contemplations

High initial investment in automation innovation

Labor force transformation and retraining needs

Balancing automation with craftsmanship and plan innovation

Ensuring quality and consistency in high-volume creation

Conclusion

Rundown of the advantages of automated clothing factories in maximizing result

The future standpoint for automation in article of clothing manufacturing

FAQs

Normal inquiries regarding the effect of automation on article of clothing creation

Suggestions for brands, manufacturers, and shoppers

Background

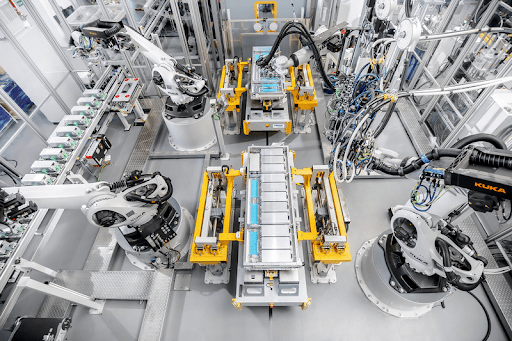

Automated clothing factories are outfitted with advanced innovations that streamline creation processes, decrease reliance on manual work, and increase the general result of articles of clothing. Key advances driving this shift include mechanical sewing machines, automated cutting frameworks, man-made intelligence driven quality control, and integrated creation management programming.

Key Parts of Automated Clothing Factories

Mechanical Sewing Machines

Outline: Mechanical sewing machines are intended to perform intricate stitching undertakings with precision and speed.

Benefits: Increases creation speed, guarantees consistent quality, and diminishes the requirement for manual work.

Automated Texture Cutting Frameworks

Outline: These frameworks use laser-directed or CNC cutting machines to precisely slice texture according to computerized designs, minimizing waste and ensuring exactness.

Benefits: Diminishes material waste, speeds up the cutting system, and takes into consideration complex plans.

Simulated intelligence Driven Quality Control

These frameworks guarantee that each piece of clothing satisfies the ideal quality guidelines.

Benefits: Decreases abandons, minimizes revamp, and guarantees consistent item quality.

Integrated Creation Management Programming

Outline: This product coordinates all parts of creation, from plan and cutting to sewing and packaging. It guarantees that the whole interaction chugs along as expected and productively.

Benefits: Streamlines tasks, enhances correspondence across divisions, and takes into account better inventory management.

Advantages of Maximizing Result with Automation

Consistent Quality Control and Decreased Imperfections: With man-made intelligence driven frameworks monitoring creation, automated factories guarantee that each article of clothing fulfills excellent guidelines, reducing the risk of deformities.

Cost Savings Through Diminished Work and Material Waste: Automation decreases the requirement for manual work and streamlines the utilization of materials, leading to significant expense savings for manufacturers.

Influence on the Design Industry

Quicker Completion times and Speed to Market: With automation, brands can decrease lead times and bring new items to showcase quicker, a pivotal advantage in the serious design industry.

Enhanced Seriousness and Productivity: Increased effectiveness and discounted costs give brands an upper hand, enabling them to offer more items at lower costs while maintaining benefit.

Sustainable Creation Practices and Decreased Ecological Effect: Automated factories are more proficient in their utilization of assets, leading to less waste and a lower natural footprint.

Difficulties and Contemplations

High Initial Investment in Automation Innovation: The expense of setting up an automated factory is significant, requiring substantial capital investment, which might be an obstruction for more modest brands.

Labor force Variation and Retraining Needs: As automation lessens the requirement for certain manual positions, there is a requirement for retraining laborers to take on new jobs in managing and maintaining automated frameworks.

Ensuring Quality and Consistency in High-Volume Creation: Automated factories should balance the requirement for high result with the need to maintain consistent quality across all pieces of clothing.

Conclusion

Automated clothing factories are unlocking new degrees of productivity and result in the design industry. As the design industry continues to develop, the force of automation will be a vital driver in meeting the demands of a quickly changing business sector, ensuring that brands can remain serious and receptive to shopper needs.

FAQs

- How do automated clothing factories increase creation yield?

Automated factories utilize advanced machinery and man-made intelligence driven frameworks to streamline the creation interaction, allowing for quicker and more productive piece of clothing manufacturing. - What are the money saving advantages of automation in piece of clothing manufacturing?

Automation diminishes the requirement for manual work, minimizes material waste, and improves creation processes, leading to significant expense savings for manufacturers. - How does automation affect the nature of articles of clothing?

Automation guarantees consistent quality through precise machinery and simulated intelligence driven quality control frameworks, reducing the risk of deformities and revise.